Vigorously transform and upgrade traditional industries, implement "Made in China 2025" in depth, accelerate the application of big data, cloud computing and Internet of Things, and promote the transformation of traditional industry production, management and marketing models with new technologies and new modes. Taking the development of intelligent manufacturing as the main target, promote the construction of national intelligent manufacturing demonstration zones, manufacturing innovation centers, in-depth implementation of industrial strong base, major equipment special projects, vigorously develop advanced manufacturing, and promote Chinese manufacturing to the middle and high-end. We will improve the manufacturing system of strengthening the country, support technological transformation in various ways, and promote the prosperity of traditional industries.

The future of China’s textile and garment industry is a manufacturing industry and a high-tech industry; a fashion industry and the service industry. How to speed up the transformation and upgrading of traditional textiles, how to improve labor productivity by advanced technology and equipment and business operations efficiency is an urgent matter for the textile industry. Intelligent manufacturing is the transformation and upgrading of China's traditional textile and garment industry, and it is the only way to become a powerful textile country.

——Speech by Premier Li Keqiang of the State Council at the 12th National People's Congress

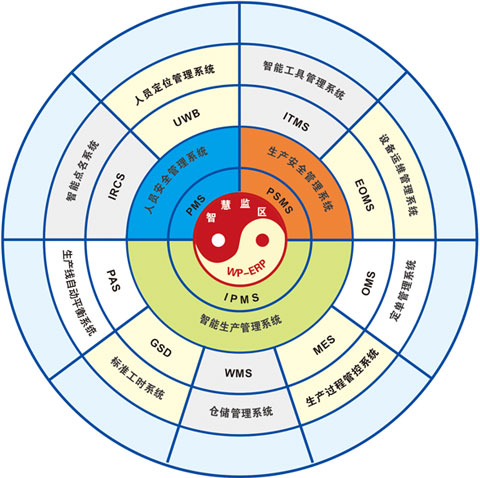

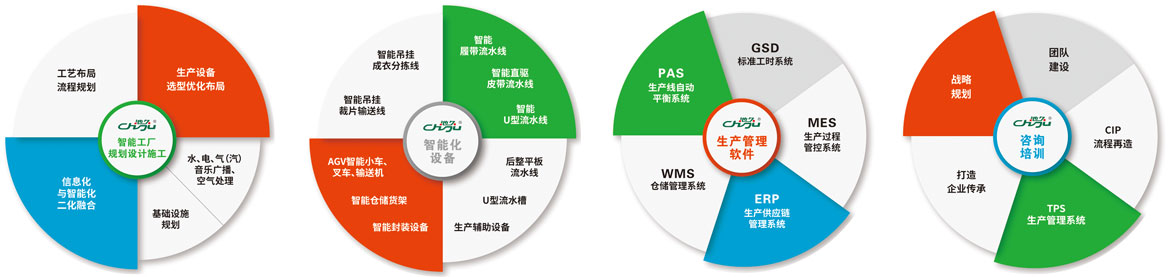

Smart factory is a new stage of modern factory information development. It is based on digital factory,using information technology and equipment monitoring technology of loT to strengthen information management and service;clearly grasp the production and sales process, improve the controllability of production process, and reduce productuon line. Manual intervention, timely and accurate collection of production line data, and reasonable production planning and production schedule. In addition, green smart means and intelligent systems and other emerging technologies are integrated to build an efficient, energy-saving, green and environmentally friendly humanized chemical plant.

GSD is one of the basic tools for data management, standardization management,lean production and intelligent manufacturing in the sewing industry.Widely used in clothing, footwear, home, luggage, handbags, leather goods,tents and other sewing products.

Performance evaluation is fair, fair and open

Piece unit price is open, fair, and public

Dispute judgment basis for piece price

Ensure that the unit price is more precise

Production improvement tool

Master a more scientific and reasonable standard operating method

Master a set of reasonable and open performance assessment tools

Master a set of methods for rational production

Process standardization

Cost rationalization

Rationalization of pricing

Get a fair, just and reasonable piece price

Master standard actions and standard operating methods

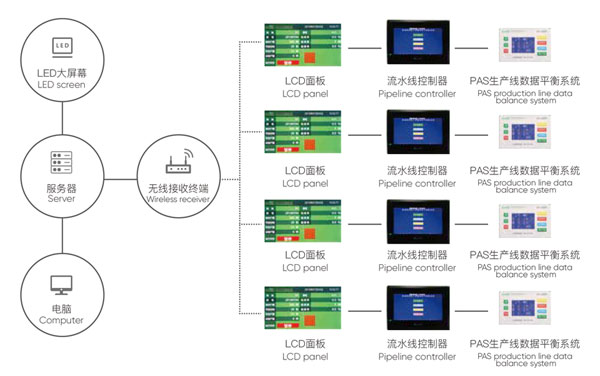

It can realize the whole process monitoring of intelligent control beat production line, realize intelligent operation, let each production station time node collect record transmission and automatic warning in real time, and generate reports. Pipeline production data and visualized kanban and back office computer data can be real-time. Docking storage summary, visual kanban page can be switched according to demand. Parking space data collection and transmission tabulation, production abnormal warning, simulated wage settlement and other functions; beat operation mode manual and automatic control arbitrary switching, with warning lights warning different states.

Staff labor compensation statistics, automatic generation of salary summary report.

Simplify complex management and make managers more clear.

It has manual and automatic operation function.

Track and collect production data, record the completion time of each station.

Ensure all production processes and bottleneck processes are synchronized, and production times flow in an orderly fashion.

Acomprehensive function of early warning and group and individual production.

MES can provide enterprises with functions including manufacturing data management, planned scheduling manage-ment, production scheduling management, quality management, project kanban management, etc. The system is customized according to the prison enterprise production environment and criminal characteristics.